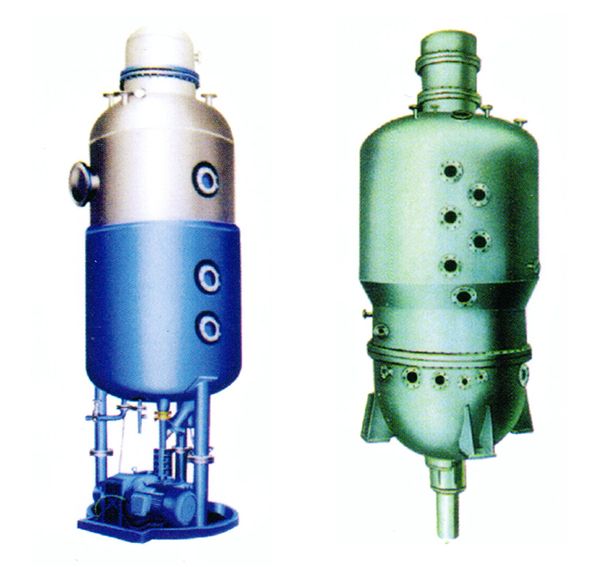

真空浓缩结晶锅

vacuum concentrating & Crystallization pot

整个设备可分为加热蒸发室、加热夹套、汽液分离器、搅拌器等四部分。我厂 在夹套加热的基础上经多方面研,设计了内加热、内循环加热,蒸发结晶锅、用户 使用后反映其蒸发效果比外加热(夹套加热)高1.8倍。

该设备与产品有接触部分,均采用1Cr18NiOTi制作,加热蒸发室、如一园筒壳体,为按装维修方便,采用不同厚度材料分两段加工,用法兰连接,封底可加工成半球形、碟形、或锥形器身上,下圆筒都装有视镜,以观察溶液沸腾状况,雾沫夹带高度,溶液的浓度,结晶大小及分布情况等,锅体内入孔是为方便清洗、维修、下锅部份焊上加热夹套,其高度通过计算蒸发所需面积而定。

搅拌目前多采用锚式搅拌器,转速6-15转/分,搅拌的按装目前采用下轴安装, 可缩短轴长度,便于安装维修。

The whole equipment consists of heat and vaporization room , heat jacket vapour-liquid separator, agitator. Our factory by mean of research on many respect and designed again in heat. In circle heat, This effect if better 1.8 times to out heat by user.

The parts of touching material liquid employ steel 1Cr18NiOTi at all. vaporization room is like a cylinder shell. It is made by two sections of upper and bekow. Thy join by flanges. Their thickness is differ, Examining and repairing is convenient. The botton is made or semisphere or dish. The bellow section fits out a peep glass. The solution boiling, fog, foam, solution thickness, crytal size and its distrbution may be saw.

Perhaps a gitator employs anchor at present, speed 6-16 P.M,and set up upper a short shaft.